Orca Slicer Speed Settings

When it comes to 3D printing, speed is great if you’re saving time — but sometimes quality matters more than a few surplus minutes. After all, there’s no point in churning out 20 pieces at once that are subpoenaed by your recycling bin due to lackluster quality as soon as the job is done. Orca Slicer Speed Settings allow you to control all of the motion parameters in your printer—from first layer speeds to travel moves so that prints are accurate, stable, and clean looking even at higher throughput.

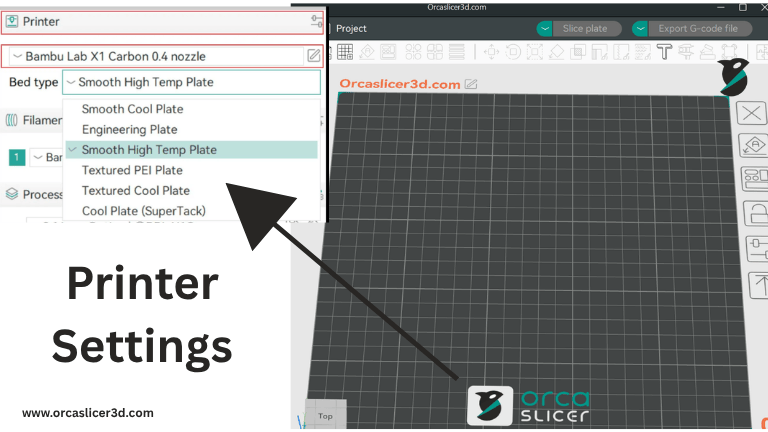

So whether you are fine tuning a Bambu Lab, Crundunu Ender or any Klipper based device, knowing each of the speed variables in Orca Slicer will help you strike the optimal balance between both speed and accuracy.

⚙️ Key Speed Settings in Orca Slicer

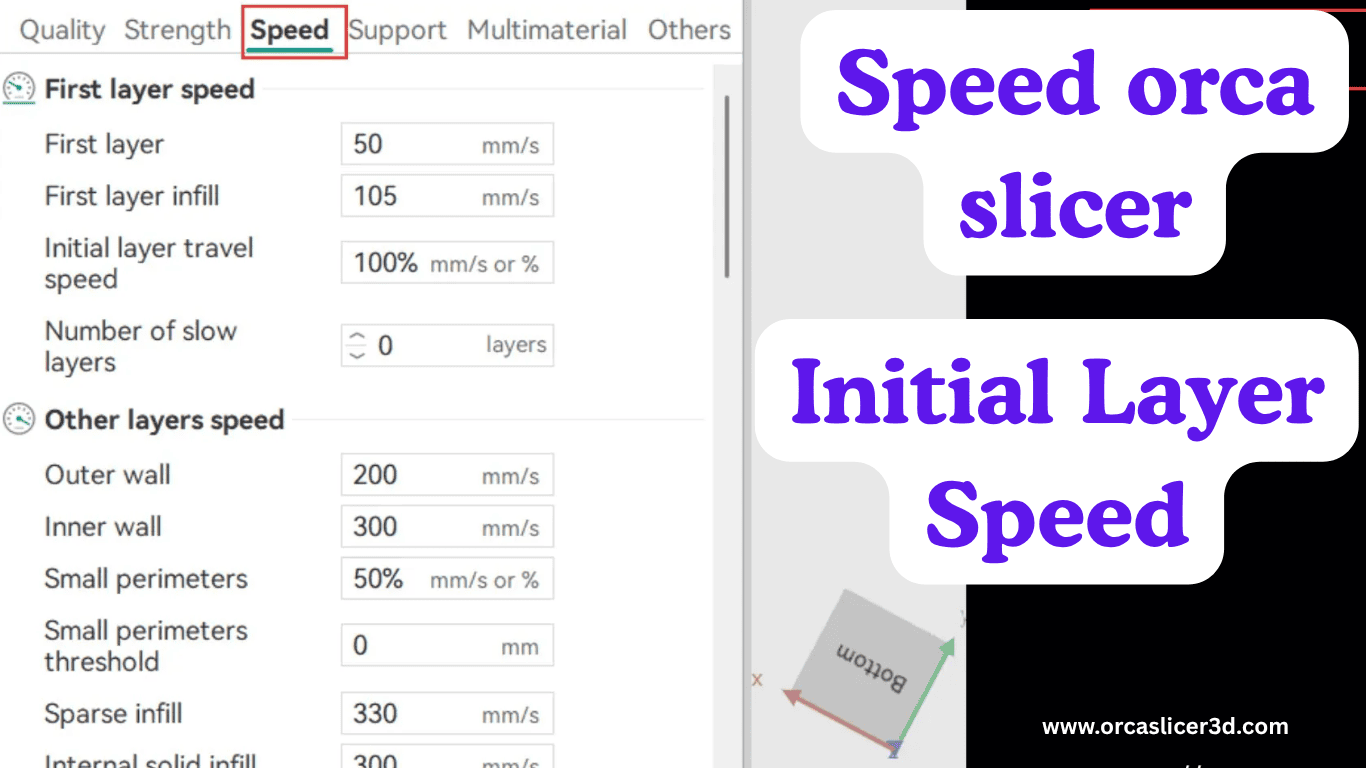

Initial Layer Speed

The first layer is the adhesion, followed by dimensionality.

Recommended: 15 – 25 mm/s

Function: Enables the filament to stick firmly into the bed which lifts over time when beginning to warp.

Tip: If you experience lifted corners, or if your first layer doesn’t look well compressed, try decreasing the initial speed in 5-mm/s increments.

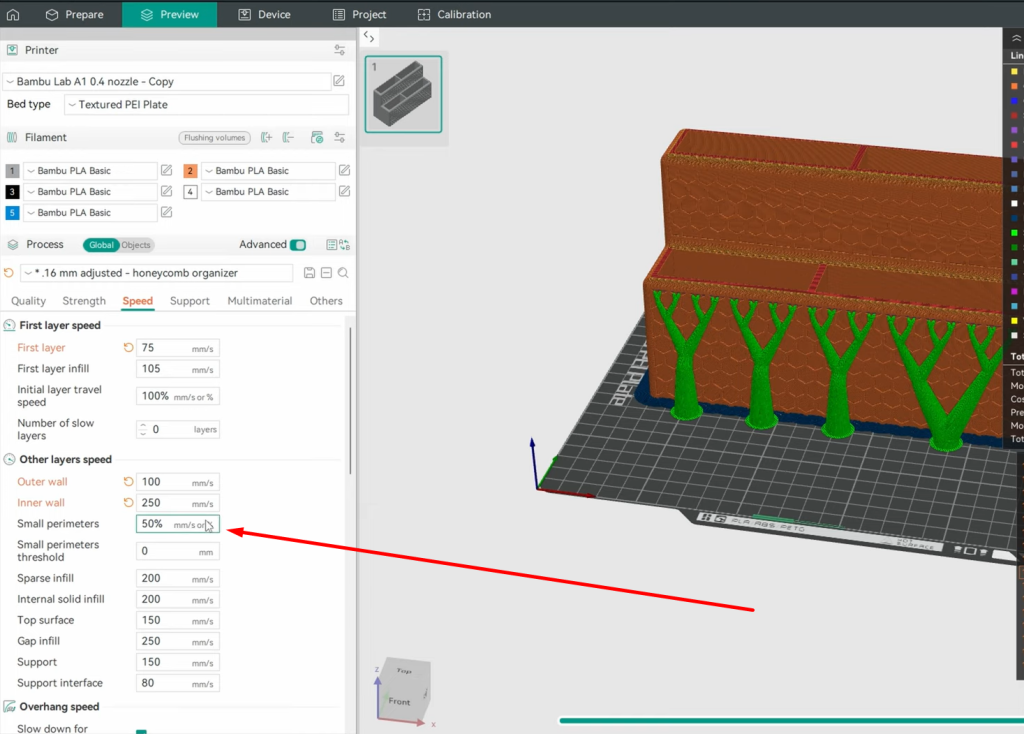

Other Layers Speed

When binding is established, speed can be increased safely.

Inner Walls: Faster speeds (50 – 70 mm/s) will save time.

Outer Walls: Lower speeds (30–40 mm/s) for a smoother finish and sharper details.

Reasoning: Correction to inner and outer wall speed ratio that reduces vibration and maintains nice features while the overall time is not sacrificed.

Overhang Speed

More gentle and cooler slow-overhangs (generally over 45°) are gaining in popularity.

Typical Range: 20 – 35 mm/s

Benefits: Keeps base dry and crispy.

Pro Tip: Combine with higher fan speeds or adaptive cooling for complex bridges.

Travel Speed

Travel moves are when the printer is moving with no filament extrusion.

Default: 150 – 250 mm/s (depending on printer rigidity).

Purpose: Idle (jerk and vibration reduction) which isn’t enough to generate frame vibration or missed steps.

Tip: If you see some ringing or ghosts near travel start, reduce this a bit, or increase acceleration limits cautiously.

Velocity and Jerk (X / Y)

Acceleration is how fast the printer can get up to its target speed, and jerk (or junction deviation in Klipper) is how abruptly it can change direction.

Higher values: More angular corners, more die stress.

Larger values: Faster prints but more risk of ghosting and/or stepper noise.

Recommended Start: Acceleration = 1000 – 3000 mm/s²; Jerk = 5 – 10 mm/s (Marlin) or 0.05 – 0.10 mm JD (Klipper).

Tuning Tip: Print a ringing test tower in Orca Slicer’s calibration tools to inspect corner artifacts before deciding.

Extrusion Rate Smoothing

This high-tech feature ensures constant flow even during speed changes.

Function: Helps reduce extrusion push force when the printer is in higher acceleration or retardation, this can make your retraction and detraction much cleaner with less under extrusion and blobs.

Advantage: Clean surfaces and uniform layer thickness, particularly where the path is curved or segmented.

When to Use: When rapid prototyping print or flexible filament that affected by retraction spike.

🧪 A Realistic Workflow for Tweaking for Speed

- Begin with the standard Orca Slicer profile for your printer.

- Change one parameter and vice a versa (e.g., only change outer-wall speed).

- Use a test model like Benchy or calibration cubes to see the effect.

- Note down the stable settings for each filament type; PLA and PETG react differently.

- Save & export profile once performance and quality match.

💡 Expert Tips

- For high-speed PETG/TPU, keep your retraction < 95 to prevent the filament being pulled back further and blobbing in the hotend.

- If ringing remains, any remaining Input Shaping compensation could be raised in firmware.

- If you want to shave off more print time, combine Lightning Infill with a tweak in travel speed.

- Keep the hotend stable: Always monitor your hotend temperature stability when increasing or decreasing speed; off temps cause inconsistent layers.

Conclusion

The Orca Slicer Speed Settings unleash high-quality performance from your regular prints, turning them into professional-grade results. Controlling how fast the nozzle accelerates, travels, and extrudes is how you dictate print quality, time, as well as surface finish. Move deliberately, measure clearly and let data — not guesswork be your guide to the final setup.